The EDM Experts

Diligently handling your most difficult cuts and features on your most valuable parts. From prototype to production, we’re here to make sure your parts are done right and delivered on time.

Contract the most knowledgeable Electrical Discharge Machining (EDM) company in Silicon Valley.

Yeah, we said it.

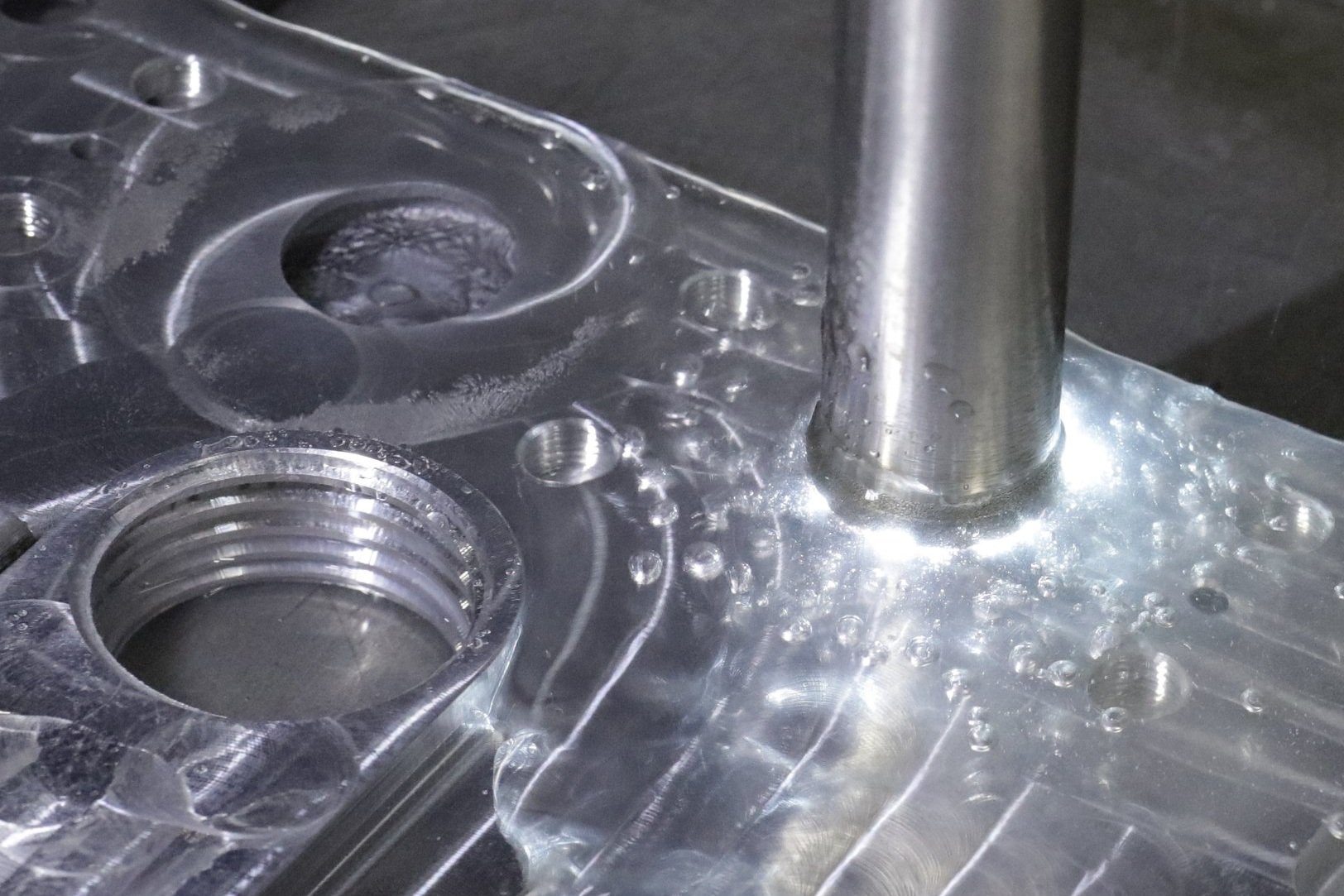

Bet you’ve never seen EDM Die Sinking in water before…

That’s because we developed it.

Innovative EDM solutions to the most difficult design challenges facing our most critical industries including semiconductor equipment, medical devices, scientific, defense, aerospace, energy, and automotive.

Unlike other machine shops, we specialize in providing EDM machining services to meet the specific needs of the core industries found in Silicon Valley and surrounding areas–the ones that make it possible for global communication, collaboration, transportation, and the many comforts of our modern world. Our experts partner with world-class manufacturers to develop impossibly precise and efficient production processes for their most complex parts using:

Clean Sinker EDM

Our proprietary water Sinker EDM machining process delivers pristine, oil-free parts.

Wire EDM is even more precise when the wire rotates…

The latest in wire tech–just for you.

Top Manufacturers Depend on Custom EDM.

For more than 50 years, our shop has been the go-to for contract EDM Machining Services of complex components to support our nation’s most critical manufacturing needs. Custom EDM was built on a passion for delivering smart, reliable, on-time solutions for EDM Sinking, Wire EDM Cutting, and Small Hole EDM Drilling–and we’ve got the proof to back it up.

World-class manufacturers rely on Custom EDM’s expertise and dedication including:

Ready to work with an EDM machine shop that gets it?

Renowned corporations bring us their most unique design challenges because they know we can develop and execute an innovative solution–often reducing production costs.

Precision machine shops bring us their most precious parts for EDM cutting and drilling because they know we’ll handle them with the utmost care and make those final cuts with the highest level of precision.